TM 9-2320-366-34-2

13-47. V-ROD CONTROL ARM REPLACEMENT

This task covers:

a. Front Removal

b. Front Installation

c. Rear Removal

d. Rear Installation

e. Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Engine shut down (TM 9-2320-366-10-1).

Driveshaft removed (TM 9-2320-366-20-4).

Tools and Special Tools

Tool Kit, Genl Mech (Item 78, Appendix B)

Goggles, Industrial (Item 28, Appendix B)

Wrench, Torque, 0-175 lb-ft (Item 92, Appendix B)

Multiplier, Torque Wrench (Item 42, Appendix B)

Wrench, Torque, 0-600 lb-ft (Item 60, Appendix C)

Socket, Socket Wrench (Item 72.1, TM 9-2320-366-20

Appendix B)

Materials/Parts

Antiseize Compound (Item 12, Appendix C)

Nut, Self-Locking (Item 220, Appendix F)

WARNING

Wear appropriate eye protection when

working under vehicle due to the

possibility of falling debris.

Failure to

comply may result in injury to personnel.

a. Front Removal.

CAUTION

Do not use a pneumatic wrench to remove

nuts, bolts from V-rod. Thread damage will

occur.

Failure to comply may result in

damage to equipment.

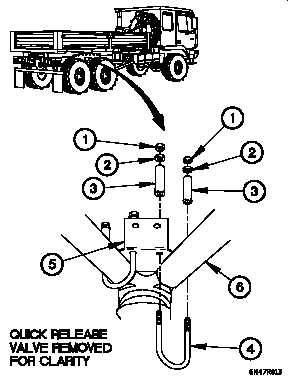

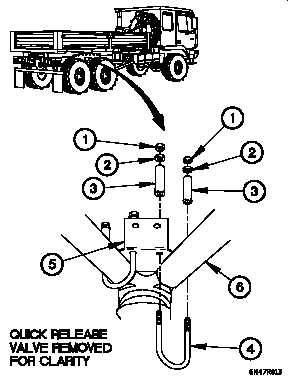

NOTE

Intermediate and rear axle quick release

valve brackets are removed the same way.

Intermediate axle quick release valve bracket

shown.

(1) Remove four nuts (1), washers (2), spacers (3), two U-

bolts (4), and bracket (5) from V-rod control arm (6).

(2) Position bracket (5) to allow access.

13-416

Change 1