TM 9-2320-366-34-2

WARNING

Compressed air used for cleaning purposes will not exceed 30 psi (207 Kpa). Use only with

effective chip guarding and personal protective equipment (goggles/shield, gloves, etc). Failure

to comply may result in injury to personnel.

(2) Dry metal parts with compressed air.

NOTE

Replace any part that fails visual inspection.

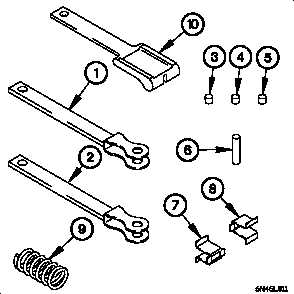

(3) Inspect levers (1 and 2) for corrosion, distortion, or

cracking.

(4) Inspect bushings (3, 4, and 5) for burrs, pitting,

corrosion, or splitting.

(5) Inspect two pivot pins (6) for burrs, pitting, corrosion,

wear, or cracking.

(6) Inspect two retainers (7) for burrs, pitting, corrosion,

wear, or cracking.

(7) Inspect two stops (8) for pitting, corrosion, wear, or

cracking.

(8) Inspect two springs (9) for pitting, corrosion, distortion, or

cracking.

(9) Inspect two plungers (10) for burrs, pitting, corrosion,

distortion, wear, or cracking.

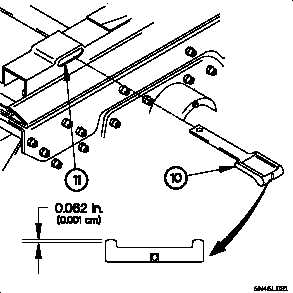

(10) Position two plungers (10) in pockets (11).

NOTE

If interference exists between two plungers

and pockets, it will be necessary to remove

0.062 in. (0.001 cm) material from top edge

of plungers.

(11) Check for interference between two plungers (10) and

pockets (11).

(12) Remove two plungers (10) from pockets (11).

(13) Remove 0.062 in. (0.001 cm) material from top edge of

two plungers (10), if required.

13-413