TM 9-2320-366-34-4

CAUTION

Cover threaded portions of rod bolts to

protect crankshaft/journals. Failure to comply

may result in damage to equipment.

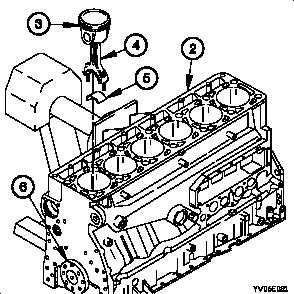

(2) Position piston (3) and connecting rod (4) in cylinder

block (2).

NOTE

Bearing tab must engage groove in connecting rod.

(3) Install upper half of rod bearing (5) on connecting rod

(4).

(4) Apply engine oil to upper half rod bearing (5).

(5) Position connecting rod (4) on crank shaft (6).

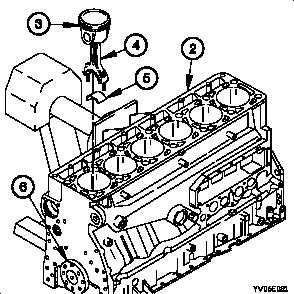

(6) Position lower half rod bearing (7) in rod cap (8).

NOTE

Bearing tab must engage the groove in rod

cap.

(7) Apply engine oil to lower half rod bearing (7) surface and

threads of rod bolt (9).

(8) Position rod cap (8) with two rod cap nuts (10) on

connecting rod (4).

(9) Tighten two rod cap nuts (10) to 35-45 lb-ft (47-61 N·m).

(10) Position alignment mark on rod cap (8) and rod cap nuts

(10).

(11) Tighten two rod cap nuts (10) a 1/6 of a turn.

f. Follow-On Maintenance.

(1) Install oil pump (para 3-17).

(2) Install cylinder head (para 3-6).

(3) Demount engine from maintenance stand (para 20-2).

End of Task.

20-49