TM 9-2320-366-34-4

25-6. M1089 STIFFLEG CYLINDER REPAIR

This task covers:

a. Disassembly

b. Cleaning/Inspection

c. Assembly

INITIAL SETUP

Tools and Special Tools

Tool Kit, Genl Mech (Item 78, Appendix B)

Wrench Set, Socket (Item 84, Appendix B)

Wrench, Torque, 0-200 lb-in. (Item 93, Appendix B)

Wrench, Torque, 0-175 lb-ft (Item 92, Appendix B)

Wrench, Torque, 0-600 lb-ft (Item 97, Appendix B)

Wrench Set, Socket, (Item 85, Appendix B)

Socket Set, Socket Wrench (TM 9-2320-366-20)

Pan, Drain (Item 43, Appendix B)

Vise, Machinists (Item 82, Appendix B)

Tools and Special Tools (Cont)

Caps, Vise Jaw (Item 12, Appendix B)

Wrench, Spanner Tool (Item 20, Appendix D)

Materials/Parts

Kit, Seal (Item 125, Appendix F)

Parts Kit, Seal (Item 320, Appendix F)

Solvent, Dry Cleaning (Item 83, Appendix C)

Lubricating Oil, Engine (Item 46, Appendix C)

Rag, Wiping (Item 60, Appendix C)

a. Disassembly.

WARNING

There may be excess hydraulic pressure

in stiffleg cylinder. Loosen plugs slowly

before removing. Failure to comply may

result in serious injury to personnel.

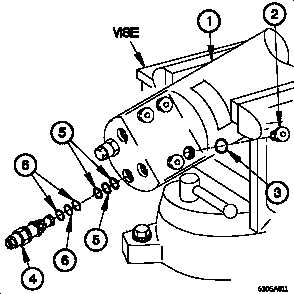

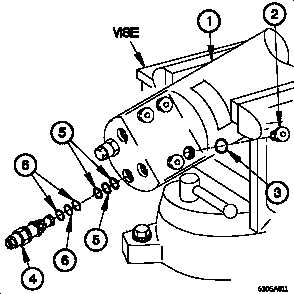

(1) Position stiffleg cylinder (1) in vise.

(2) Place drain pan under stiffleg cylinder (1).

(3) Remove four plugs (2) from stiffleg cylinder (1).

(4) Remove four preformed packings (3) from plugs (2).

Discard preformed packings.

(5) Remove two counterbalance valves (4) from stiffleg

cylinder (1).

(6) Remove three preformed packings (5) and back-up rings

(6) from two counterbalance valves (4).

Discard

preformed packings and back-up rings.

25-28