TM 9-2320-366-34-3

16-77. M1089 FOLDING BOOM FRAME ASSEMBLY REPAIR

This task covers:

a. Disassembly

b. Cleaning/Inspection

c. Assembly

d. Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Engine shut down (TM 9-2320-366-10-1).

Hydraulic reservoir supply and return valves

closed (TM 9-2320-366-10-2).

Stinger cylinder removed (para 16-70).

Tools and Special Tools

Tool Kit, Genl Mech (Item 78, Appendix B)

Wrench, Torque, 0-175 lb-ft (Item 92, Appendix B)

Wrench Set, Crowfoot, Ratcheting (TM 9-2320-

366-20)

Sling, Cargo (2) (Item 56, Appendix B)

Goggles, Industrial (Item 28, Appendix B)

Gloves, Rubber (Item 26, Appendix B)

Pliers, Retaining Ring (Item 44, Appendix B)

Materials/Parts

Cap and Plug Set (Item 17, Appendix C)

Rag, Wiping (Item 60, Appendix C)

Dispenser, Pressure Sensitive Adhesive Tape

(Item 30, Appendix C)

Ties, Cable Plastic (Item 92, Appendix C)

Sealing Compound (Item 76, Appendix C)

Solvent, Dry Cleaning (Item 83, Appendix C)

Nut, Self-locking (2) Item 176, Appendix F)

Adhesive, Silicone Sealant (Item 4, Appendix C)

Grease, Automotive and Artillery (Item 35,

Appendix C)

Personnel Required

(3)

a. Disassembly.

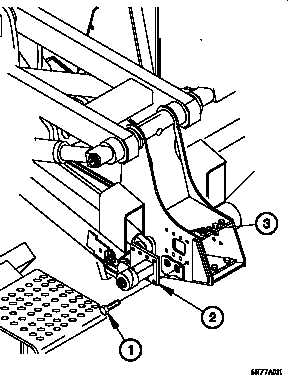

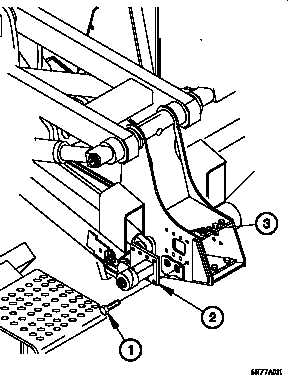

(1) Remove eight screws (1) and camlock (2) from folding

boom frame (3).

16-457