TM 9-2320-366-34-1

2-1101

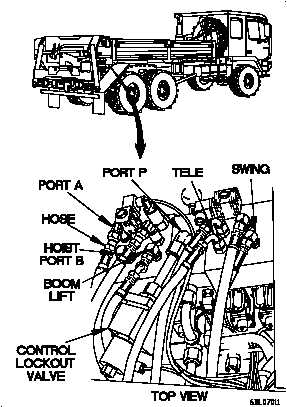

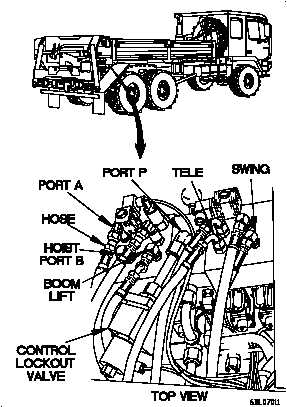

FOUR WAY CONTROL VALVE ASSEMBLY FLOW TEST

NOTE

Test in worst direction (tele in or tele out).

To select tele in: substitute port B for

port A, in steps (1), (2), (12) and (13); in

step (6) operate tele in and in step (7)

observe reading of about 4 gpm

(15.2 lpm).

(10) Stow MHC (TM 9-2320-366-10-1).

(11) Position MHC power switch to OFF (TM

9-2320-366-10-1).

(12) Position PTO switch to off (TM

9-2320-366-10-1).

(13) Shut down engine (TM 9-2320-366-10-1).

(14) Disconnect hydraulic tester, hoses and

adapters from port A and hose.

(15) Connect hose to port A.

(16) Remove drain pan from under vehicle.

(1) Place drain pan under vehicle.

(2) Disconnect hose from port A of boom

telescoping control valve in four way (upper)

control valve assembly.

(3) Connect hydraulic tester between hose and

port A with test hoses and adapters.

(4) Start engine (TM 9-2320-366-10-1).

(5) Position PTO switch to on (TM

9-2320-366-10-1).

(6) Increase engine RPM to 1250-1450 RPM (TM

9-2320-366-10-1).

(7) Position MHC power switch to ON (TM

9-2320-366-10-1).

(8) Operate MHC telecsope out (TM

9-2320-366-10-1).

(9) Observe reading of about 8 gpm (30 lpm).

If flow is low, replace boom telescope control

valve in four way control valve assembly.

If boom will only work in tele in position,

perform visual inspection of telescopic

out lockout valve. Replace damaged

telescopic out lockout valve. If necessary,

perform electrical troubleshooting

(e115. M1084/M1086 MHC Overload

Shutdown System Stays Activated).

WARNING

Wear approved eye protection when performing

pressure checks. Failure to comply may result

in oil getting into eyes. If oil contacts eyes, seek

medical attention immediately.

Drop hydraulic pressure to zero before

disconnecting any hydraulic hose, tube, or fitting.

Failure to comply may result in injury to personnel.

Fuel and oil are slippery and can cause falls.

Wipe up spilled fuel or oil with rags. Failure

to comply may result in injury to personnel.