TM 9-2320-366-34-1

2-1097

MOTOR FLOW TEST

(9) Stow MHC (TM 9-2320-366-10-1).

(10) Position MHC power switch to OFF (TM

9-2320-366-10-1).

(11) Position PTO switch to off (TM

9-2320-366-10-1).

(12) Shut down engine (TM 9-2320-366-10-1).

(13) Disconnect hydraulic tester, hoses and adapters

from port V2 and hose.

(14) Connect hose to port V2.

(11) Position PTO switch to off (TM

9-2320-366-10-1).

(12) Shut down engine (TM 9-2320-366-10-1).

(13) Disconnect hydraulic tester, hoses, adapters,

and STE/ICE-R accessories from fitting and hose.

(14) Connect hose to fitting.

(15) Remove drain pan from under vehicle.

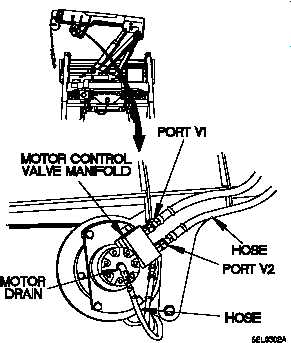

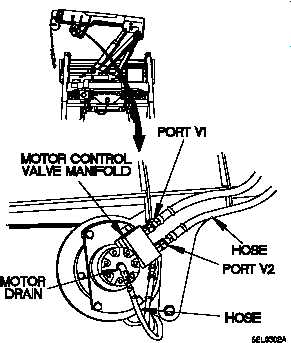

(1) Disconnect hose from port V2 on hydraulic

motor valve assembly.

(2) Connect hydraulic tester input to port V2

and output to hose with test hoses and

adapters.

(3) Start engine (TM 9-2320-366-10-1).

(4) Position PTO switch to on (TM

9-2320-366-10-1).

(5) Increase engine RPM to 1250-1450 RPM (TM

9-2320-366-10-1).

(6) Position MHC power switch to ON (TM

9-2320-366-10-1).

(7) Operate MHC to raise a moderate load with

hoist.

(8) Observe flow of 7-9 gpm (27-34 lpm) and

pressure of less than 2250-2550 psi

(15514-17582 kPa). If step fails, repair or

replace holding valve (para 16-18).

HOIST HYDRAULIC MOTOR VALVE ASSEMBLY

FLOW TEST

(1) Disconnect hose from motor drain fitting.

(2) Connect hydraulic tester between hose

and motor drain fitting with test hoses,

adapters, and accessories from STE/ICE-R.

(3) Start engine (TM 9-2320-366-10-1).

(4) Position PTO switch to on (TM

9-2320-366-10-1).

(5) Increase engine RPM 1250-1450 RPM (TM

9-2320-366-10-1).

(6) Position MHC power switch to ON (TM

9-2320-366-10-1).

(7) Operate MHC to raise a moderate load with

hoist.

(8) Observe flow of 7-9 gpm (27-34 lpm) and

pressure of less than 2250-2550 psi

(15514-17582 kPa).

(a) If pressure is high and flow is low, check

valve on hoist is faulty.

(b) If flow and pressure are low, replace

hoist hydraulic motor.

(9) Stow MHC (TM 9-2320-366-10-1).

(10) Position MHC power switch to OFF (TM

9-2320-366-10-1).